Alka's „Prăjitura Casei" was born in 2006, out of the desire to bring a simple, good and authentic dessert to Romanians' tables – just like it's made at home. From the beginning, a team of dedicated specialists, who do their job with passion, worked on the recipe for this cake to preserve the sweet taste of childhood and family traditions.

The name „Prăjitura Casei" was not chosen by chance: each recipe starts from the same idea – using high-quality ingredients, exactly like those you would use in your own kitchen.

Today, „Prăjitura Casei" is produced in modern facilities, with advanced technology and in accordance with the strictest quality and food safety standards. Beyond equipment and processes, the human factor remains essential: the Alka team, made up of dedicated and passionate people, who put their soul into each product and truly love what they do.

The ingredients used in our cakes are of the highest quality, being subject to strict traceability controls, internal audits and certifications, in accordance with national and European legislation. One of these is the egg, a basic ingredient that provides texture, consistency and color, having a significant impact on the taste and appearance of the cakes. The acquisition of this ingredient, like the others, is carried out from rigorously selected producers, who comply with strict quality and food safety standards, both at national and European level. They are evaluated annually, including on the basis of ethical and social responsibility criteria.

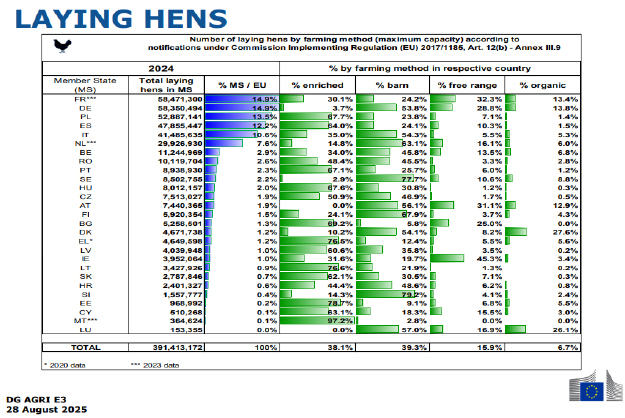

At European level, there are over 350 million laying hens, which produce almost 6.7 million tons of eggs annually. The European Union strictly regulates the market, supporting farmers through clear standards and support measures.

In Romania, according to the most recent statistical data published by the European Commission (agriculture.ec.europa.eu), the distribution of laying hens by rearing systems is as follows:

• 48.4% – "Enriched" system (enriched cages, code 3);

• 45.5% – "Barn" system (free range in closed halls);

• 3.3% – "Free Range" system (daytime outdoor access);

• 2.8% – "Ecological" system (natural, organic feed and compliance with the strictest animal welfare and environmental protection standards).

At the European Union level, the structure is different:

• 38.1% in the "Enriched" system;

• 39.3% in the "Barn" system;

• 5.9% in the "Free Range" system;

• 6.7% in the "Organic" system.

These data show that the distribution of eggs from "Enriched" systems is a challenge at European level, being influenced by economic realities and the level of accessibility for consumers. In some Member States, important producers such as Spain or Poland, the share of this type of eggs even exceeds 60%, confirming that the complete transition to alternative cage-free systems is not uniform and easy to achieve at European level.

Such a change requires very large investments from farms, a reduction in productivity by 25–30% with direct effects on the availability of eggs on the market and, implicitly, an impact on prices and accessibility for consumers.

Concrete steps taken by Alka towards the cage-free transition

Alka takes society's expectations regarding sustainability and animal welfare seriously.

Starting in June 2023, we have significantly reduced the amount of eggs from enriched cage systems (code 3) used in the production of cakes. This is a real step in our continuous process of optimization and responsible innovation.

We want the transition to cage-free eggs to take place and are ready to fully comply when there is a clear legislative framework at European level, equally applicable to all industry players. Such an approach would ensure a level playing field, price stability and the protection of jobs (over 1,000 employees in our case), allowing a sustainable transition to cage-free alternatives.